Differences between cavitators, their application in hydrodynamic facilities of UKG

The main factors determining the value of the fuel, is its t e plotvornaya ability, determines the amount of heat generated by the complete combustion unit fuel mass, physical properties of the working t e la, contents of harmful impurities in the flue gases.

One of the most radical means to improve the efficiency of thermal power plants is to improve the qualitative characteristics of the fuel, enabling to intensify the combustion process is one of the receive and gical fuel mass greater amount of energy. Particularly when used in d izelnyh engines and boilers employing highly viscous fuel oils, n of the beam from a residual refinery fractions.

Improved energy and environmental indicators teploenergetich e Sgiach complexes basically achieved through improvements etc. of processes of fuel combustion.

In heavy fuel oil, as the final product of oil refining, the heaviest hydrocarbon fractions, products of thermal cracking, oxidation, polymerization, coking, are concentrated; non-combustible ballast, consisting of mineral mass, metals, ash, mechanical impurities. In the process of Cracks n n residual fraction depleted in hydrogen, which leads to reduction of heat of proach ability zharoproizvoditelnosti oil. Fuel oil quality has deteriorated and etsya in transport time, long-term storage of fuel oil in the tanks of the Oka with the wish to set up, is polymerized , saturated with biological organisms, watered; as a result of chemical reactions, fuel oil hydrocarbons turn into solid precipitated products.

The experience of operating boilers on heavy grades of fuel has shown the full dependence of their long-term, reliable and efficient. operation from kaches t wa prepare fuel for combustion. Compounds, included in the residual is not p tyanyh fuels, asphaltenes , resins, jelly condensations have long developed molecular chain, with no highly stable bonds C- C, which can be broken under the influence of high frequency oscillations due to mass transfer and n GOVERNMENTAL processes between layers of the processed environment.

After the destruction of high-frequency acoustic oscillations length n GOVERNMENTAL hydrocarbon molecules formed integral light active radicals n sively mixed whirling flow in the bulk treating medium adt at Payuta reacted with molecules of residual hydrocarbon fractions

Cavitators Review

Currently, a host of devices in the world, allowing in s wake in fluid cavitation process (formation of the cavities with a negative pressure). All calculations and practice show that the magnitude of the cavitation Mr. Noah cavity depends on the speed of the collapse, and hence the degree of exposure to a liquid for STI that are in the collapse zone. Ways excitation cavitation Ms d bones all four .

- Using ultrasonic vibrations of the magnetostrictor membrane . The vacuum wave zone formed by the membrane vibrations also proish about dit formation of cavitation processes.

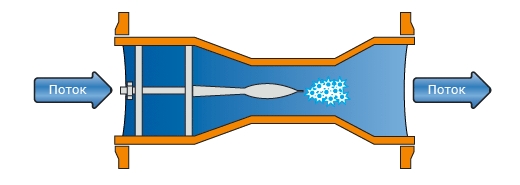

- With the help of flow tubes with a variable cross-section or to the special and measures swirls ( fyusonik ). The principle is that with a sharp drop in pressure, cavitation cavities form at the transition boundary.

- by rotating the rotor in the flow stream (impeller) opred e lennogo profile.

- Using a sharp break in the fluid flow mechanically.

- Magnetostrictors

The most expensive and inefficient magnetostrictor is because of the very expensive electronic-power part that excites the membrane.

In Japan and Switzerland, such devices are used in pharmaceutical and perfumery and cosmetic production. The cost of these devices with a capacity of 0.5 m 3 / hour, can reach up to 2 000 000. But with low productivity and high cost, such devices are both unreliable and expensive to operate and repair.

- Cavitators type FYUSONIK

Such an apparatus is a pipe of variable cross-section, without moving parts, without an engine and electronics .

Such devices produce the weakest effect on the processed fluid, due to the fact that:

- cavitation does not occur in the entire volume, liquid

- impossibility constant SUPPORTED and Nia optimal operation - in dependent and . Ing on the temperature, pressure, viscosity and other physical and chemical parameters of treating the e my liquid

- to achieve the most complete rarefaction of the stream is almost impossible

- possible effect of adhesion of fuel oil, which drastically affects so camping on the quality and derivatives and telnosti

- requires multiple processing of the same volume of liquid in order to achieve a more or less homogeneous emulsion.

- high dispersion VME - 10 microns

These disadvantages are not offset by such advantages as:

- does not contain fast wearing d e hoists, seals, rotation units, maintenance-free

- not critical to withstand high temperature and pressure and fuel oil height of the intense heat (up to 20 atm and 150 deg.).

- cheaper to manufacture

Apparatus neko toryh cavitators type Fyusonik

One of the varieties of cavitators of this type is cavitators where ultrasonic vibrations in a fluid flow are excited by a body vibrating in a flow with a high frequency.

- Bladed cavitators

They are a pipe in which fluid flows, an impeller of a certain profile rotates in the fluid. Cavitation occurs due to rarefaction of the flow behind the blade.

Cavitation is more intense than cavitators of the FYUSONIK type due to the repeated occurrence of cavitation in a unit volume.

- to achieve the most complete rarefaction of the stream is almost impossible

- cavitation does not occur in the entire volume, liquid

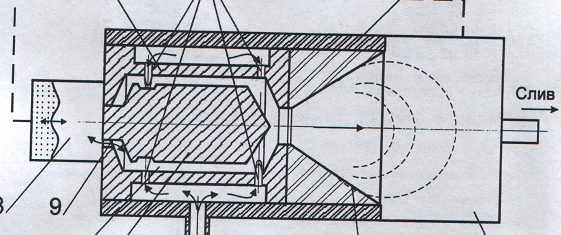

- Hydrodynamic sirens

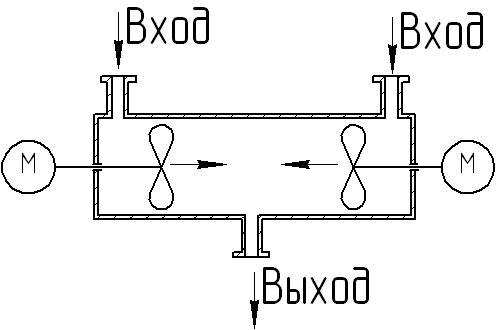

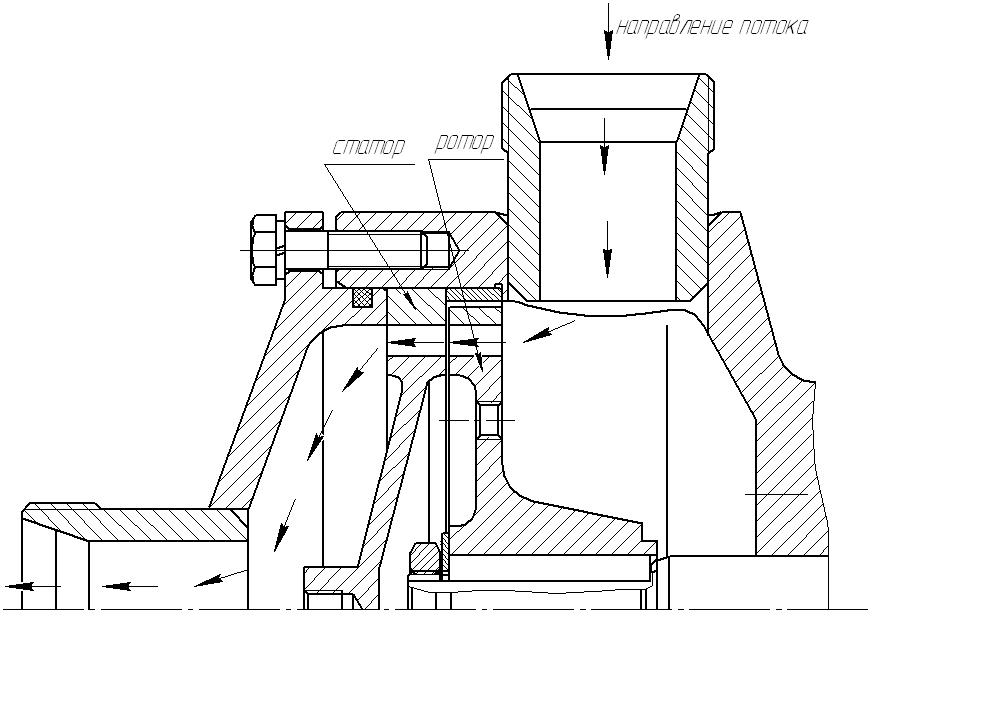

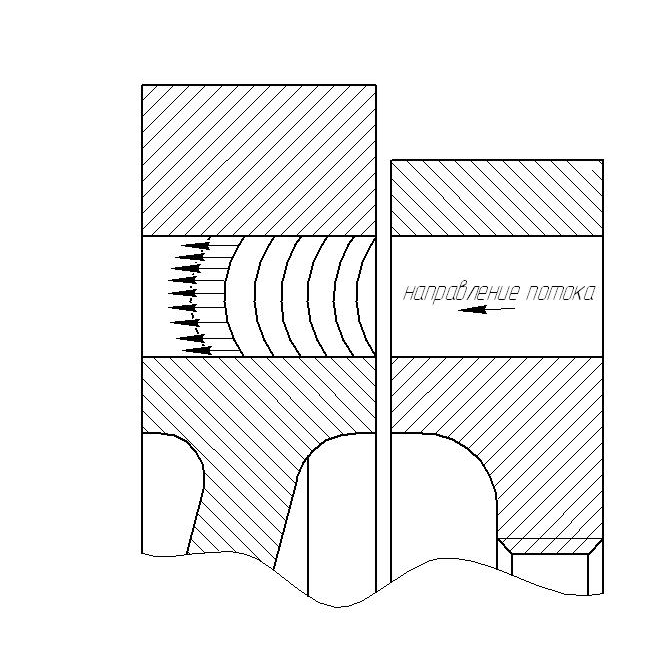

They are a casing with inlet and outlet pipes installed in it, a concentric rotor and a stator with windows made in them are installed in the casing. Due to the fact that the windows in the stator periodically open and close, there is a periodic interruption of the TOTAL fluid flow, the number and size of the windows are selected in such a way that the TOTAL fluid is processed.

The disadvantage of such cavitators :

- abrasive wear of the working surfaces of the rotor and stator, as a result of which their periodic replacement is required,

- The inability to technologically fulfill the gap between the rotor and the stator is less than 0.1 mm.

The principle of operation is discussed below on the example of our cavitator.

- Our cavitators - further development of hydrodynamic sirens

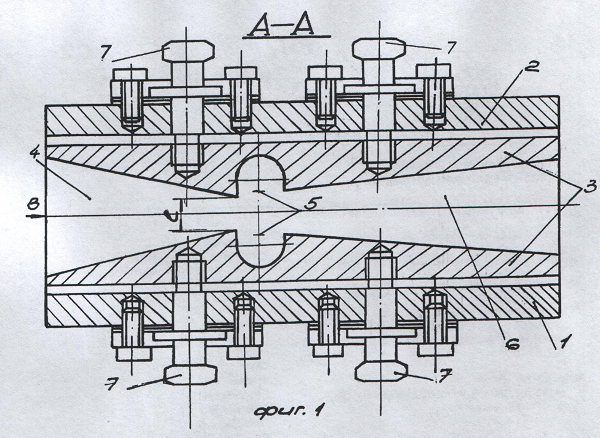

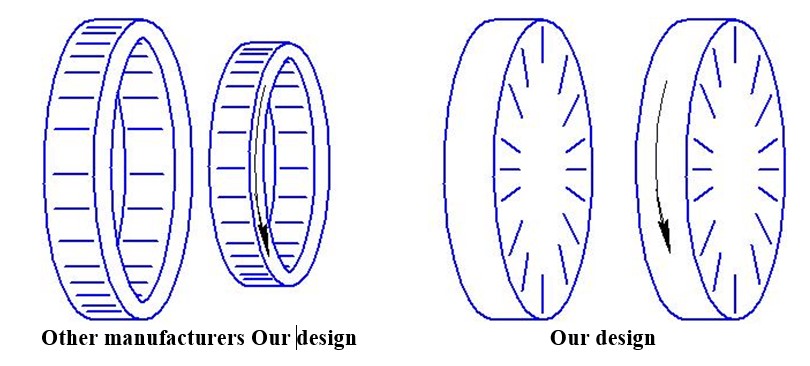

The main distinguishing feature of our installations is the design of the working parts (stator and rotor).

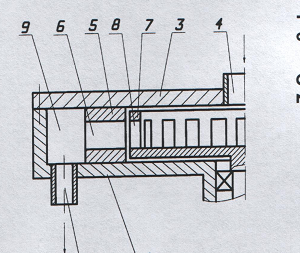

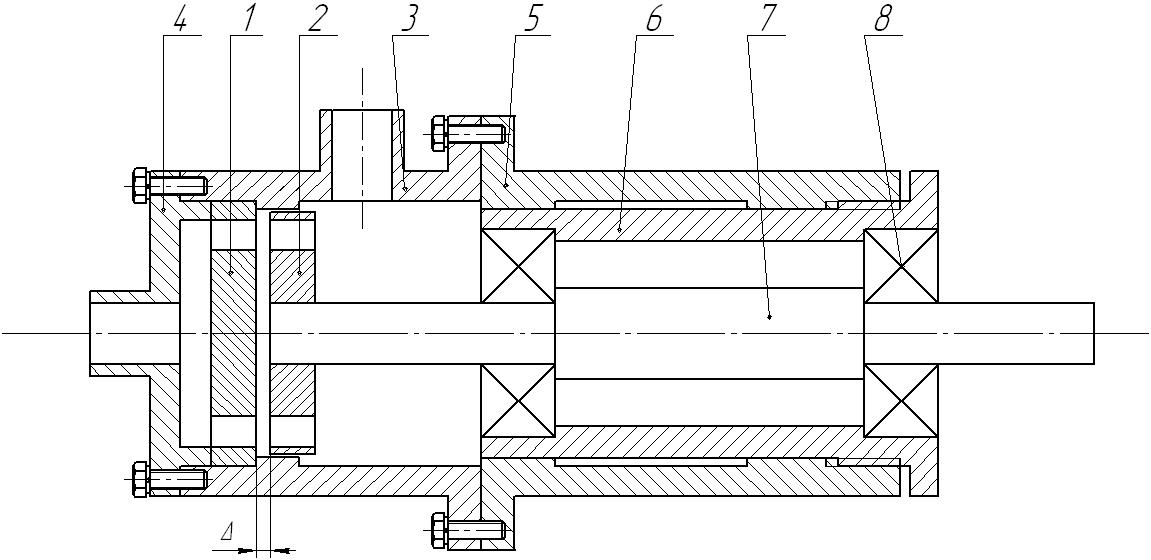

Our design allows you to easily remove wear on the working parts and adjust the gap between the stator and the rotor without dismantling the installation.

Other designs do not allow to eliminate wear in the gap. You have to immediately change the pair of stator and rotor, which is very expensive and time consuming.

The sealing assembly on our plants is fundamentally different from other designs.

Adjustment of the gap between the stator and the rotor.

Δ on the gap between the stator and the rotor depends yn intensity cavitation proce with a s , arising in the stator channels. Ideally, this gap should not exist at all in order to prevent overflows in the gap.

During the operation of the apparatus, the temperature of the working parts and the shaft changes, which leads to a change in the gap, which in turn can lead to mashing of the stator and rotor.

This design allows you to quickly adjust the gap directly on the installation, heated up during operation, and adjust the minimum clearance.

- Stator

- Rotor

- Emitter housing

- case cover

- Fixed body

- Movable housing

- Shaft

- Bearing

The clearance is adjusted by moving the movable housing in motionless on the seating surfaces by means of a thread cut into the housings.

Principle of operation.

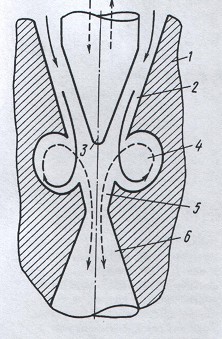

The fluid flow during processing passes through a rotating rotor and a stationary stator of the installation.

The fluid flow during processing passes through a rotating rotor and a stationary stator of the installation.

The rotor acts as a shutter, periodically interrupting the flow, the smaller the gap between the rotor and the stator, the more tight the shutter, the more intensive the processing. The main processes occur in the stator.

Consider the example of images.

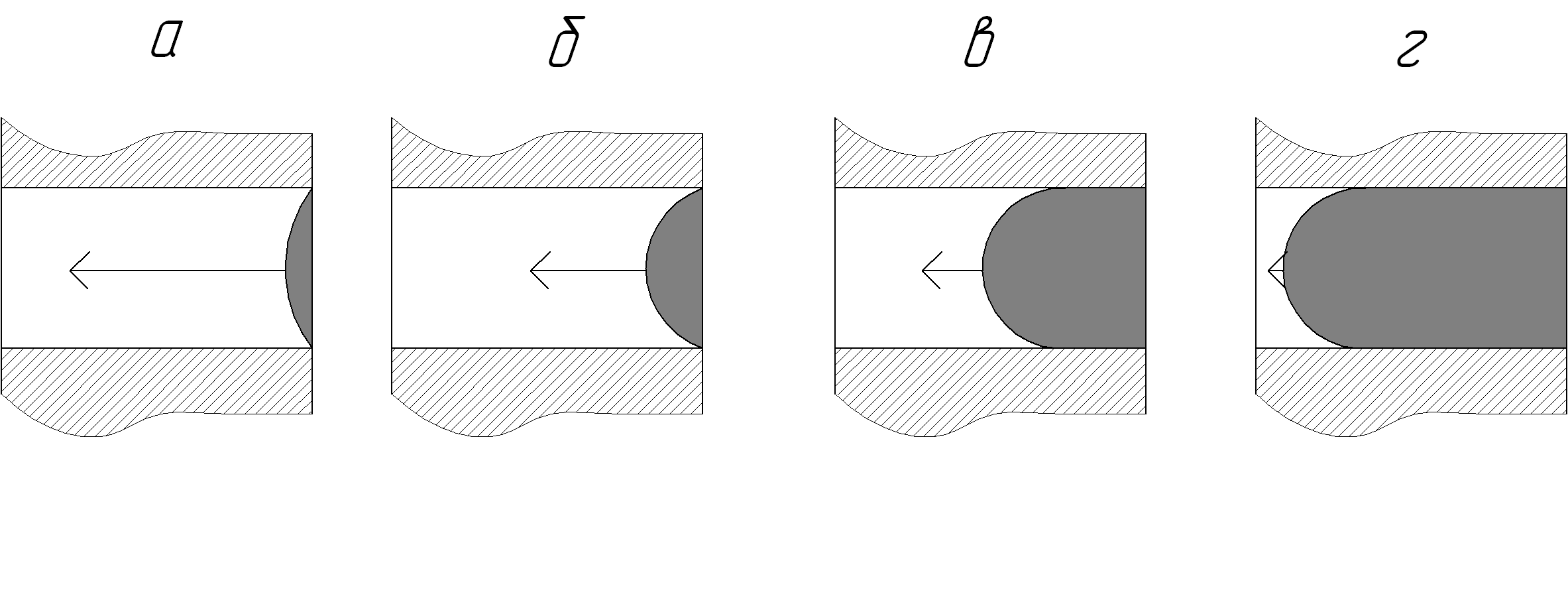

- When the windows of the rotor and the stator coincide, the flow moves through them with a certain speed. The speed depends on the initial pressure in front of the rotor (pump pressure).

- When the rotor overlaps the stator window.

A sharp flow break occurs. But since the liquid has a mass, it does not stop instantly, it continues its movement stretching. Due to this, the pressure inside it decreases. Boiling up of gases dissolved inside the liquid occurs and the formation of the so-called cavitation cavity. At a certain moment, the fluid inertia forces are compared with the resulting atmospheric pressure force and the vacuum force inside the cavitation cavity

a, б, в - in the growth of the cavitation cavity, a decrease in the force of inertia, г - equilibrium

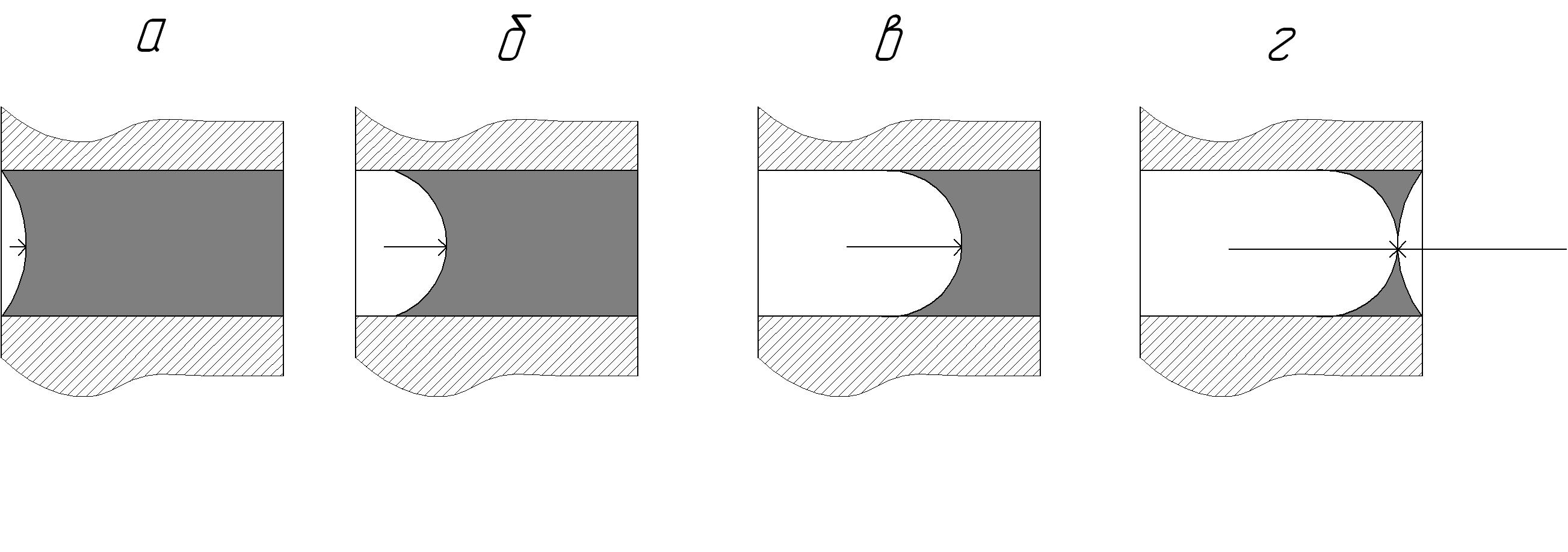

- Behind the equilibrium point, the following processes begin to occur:

The inertia force decreases to 0 (due to inhibition of the liquid by rarefaction in the cavitation cavity), and since there is no additional backwater, then the negative pressure inside the cavity begins to exceed the resulting force and the process of collapse of the cavitation cavity (bubble) occurs . Because the liquid is poorly compressed and poorly stretched, then upon the termination of the action of external forces (inertia forces), the process of collapse occurs very intensively.

a, б, в — collapse of the cavitation cavity; increase in flow velocity; г — water hammer.

- At the moment of completion of the process of collapse of the cavitation cavity, another coincidence of the rotor and stator windows occurs and the next portion of liquid enters the rotor cavity, thereby increasing the speed of collapse to some extent. Further, at the time of the final closure of the cavitation cavities occur fluid front 2: front collapse of the cavitation cavities and front moving fluid occurs rod droudar, further stressing s intensivnos t s processing.

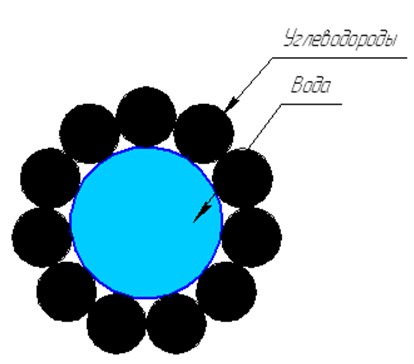

During the preparation of the emulsion, the water is divided into drops of 1-3 microns in size, water droplets are evenly distributed throughout the fuel volume and become a dipole. Fragments of hydrocarbon molecules adhere to this dipole and micelles form (a ball with a drop of water inside). It is the presence of micelles that explains the resistance of the emulsion to delamination. Water droplets do not merge into larger ones due to the presence of a hydrocarbon shell, and the shell does not come off the droplet due to the presence of a charge in it.

During the preparation of the emulsion, the water is divided into drops of 1-3 microns in size, water droplets are evenly distributed throughout the fuel volume and become a dipole. Fragments of hydrocarbon molecules adhere to this dipole and micelles form (a ball with a drop of water inside). It is the presence of micelles that explains the resistance of the emulsion to delamination. Water droplets do not merge into larger ones due to the presence of a hydrocarbon shell, and the shell does not come off the droplet due to the presence of a charge in it.

At the time of the injection of such an emulsion into the combustion zone, the following occurs:

A micelle, ranked in the combustion zone , begins to heat, the boiling point of water and heavy oil differ greatly (water 100 0 C fuel oil of about 300 0 C), water boils up sharply, fuel at this time is still in the liquid state and prevents the evaporation of water droplets. When the critical pressure is reached inside the micelle, microexplosion occurs (water vapor breaks its shell and sprays it). There is a multiple increase in the area of contact between fuel and oxygen, this leads to the same effect as atomization of fuel at a nozzle pressure of 150-300 kg / cm 2 . That’s the whole secret of the process, all the savings are only due to a more complete combustion of the original fuel oil. And the worse the boiler is configured, the worse the initial fuel, the greater the savings. And this does not mean that if the water content in the emulsion is 10%, this directly proportionally leads to a 10% fuel economy. Depending on many factors, this economic effect can be 8–9% and 18–20% and 24–34%. This data is from many years of experience implementing our facilities. We guarantee fuel savings of 7-8%, but this does not mean that it cannot be 15 and 18 and 25%. Once again, it depends on many factors (settings of the boiler, burners, quality of the initial fuel, its calorific value and water cut , temperature). But one thing is for sure, an emulsion containing even 40% of water will burn, which is completely impossible , if the water is just water as a fuel composition.

In addition, during the burning of the emulsion, the temperature of the exhaust gases decreases (without decreasing the temperature in the furnace and boiler productivity), this indicates an increase in the efficiency of the boiler itself.