Cavitation unit for oil treatment MUPN

MUPN - a modular installation for the preparation of oil. The main field of application of MUPN is the preparation of finely dispersed solutions of an emulsion structure that are resistant to delamination with various modifier additives. Processing with a cavitation device RAF, which is the main assembly unit, allows one to obtain stable emulsions that are not subject to spontaneous destruction with time and are resistant to freezing and defrosting.

ADVANTAGES

- Universality. Using MUPN, it is possible to produce high-calorie environmentally friendly fuel, reduce the viscosity of diesel fuel, introduce additives in fuel and lubricants, and utilize sludge.

- Suitability for operation at low temperatures. The built-in heating system maintains the set temperature of the components necessary for obtaining high-quality finely dispersed solutions.

- Full compliance with technical regulations and GOSTs. MUPN produced in accordance with the requirements for oil equipment and equipped with advanced security systems.

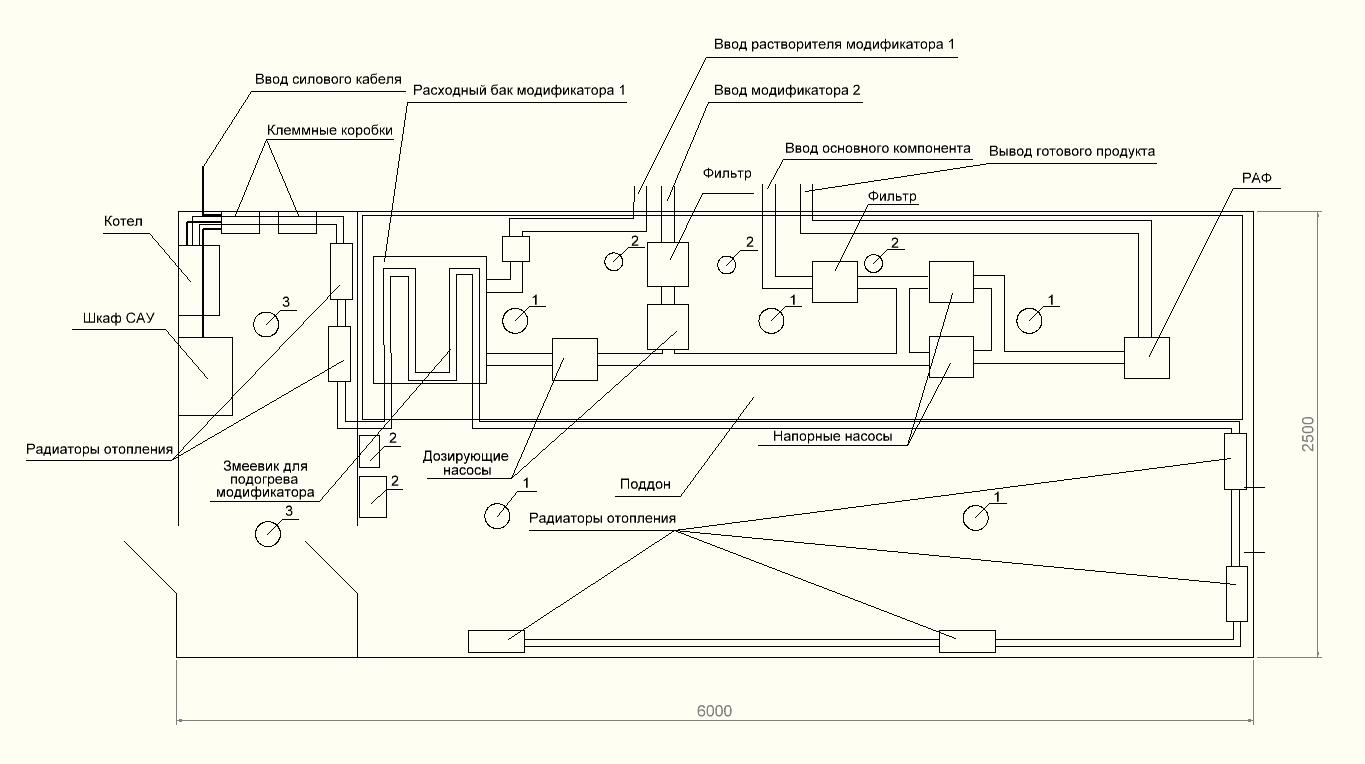

Cavitation hydrodynamic unit MUPN is made in a steel container with two compartments. The first part contains installation parts, the second contains the control and monitoring panel. MUPN consists of a piping system, a dispersant of hydrodynamic RAF, equipment for heating the units, metering and pressure pump units, tanks for emulsion components, and a control and monitoring system. MUPN is equipped with an automatic fire extinguishing system.

Specifications:

- Productivity (in m3 / h of finished emulsion) - 35 m3 / h;

- Maximum electric power consumption 45 kW / h;

Design

The installation is an insulated block container with an entrance group of dimensions 6.0 / 2.5 / 2.4 meters, having a welded metal frame and divided into 2 rooms.

In the first room are:

- electric boiler for local heating,

- automatic control cabinet

- 2 terminal boxes.

In the second room is the installation UKG14-35, consisting of:

- modifier supply tank No. 1,

- solvent supply pump modifier No. 1,

- dosing pump modifier No. 1,

- filter and dosing pump modifier No. 2,

- fine filter of the main component,

- pressure pumps for supplying the mixture,

- cavitator (RAF).

The premises are heated by 6 radiators connected to the local heating boiler . The modifier consumable tank is heated by a coil connected also to the heating boiler.

Explosion-proof luminaires (1) with explosion-proof switches, luminaires for general industrial lighting (3) are used for lighting.

A fire extinguishing system is present in the block container, including:

- thermal sensors

- gas sensors

- Sprayers

- powder fire extinguisher tank,

- automatic fire extinguishing systems.

VARIATIONS OF EXECUTION

Equipment may include additional lines for the accurate and uniform dosing of additives and chemicals to modify the feedstock. It can be delivered in various variations:

- Semi-automatic performance. In which, for the operation of the equipment, our specialists are trained in the operator servicing the installation and regulating the processes.

- Full automatic execution. In which all processes are controlled by a computer designed exclusively for the needs of the customer, the presence of the operator in this configuration is minimized.

To purchase the MUPN cavitation installation, contact the sales department at the numbers indicated on our website or leave a request in the feedback form.

SCHEME OF WORK