Cavitation facilitie UKG-14

UGK-14 units are capable of processing up to 18 m3 / h of the initial product, which can be various kinds of oil products (fuel oil, liquid heating oil, oil sludge , diesel fuel), and food products to be mixed (preparation of sauces, mayonnaise, creams).

To work with food products, a special installation option is produced, the contact surfaces and pipelines of which are made of neutral materials - for example, stainless steel.

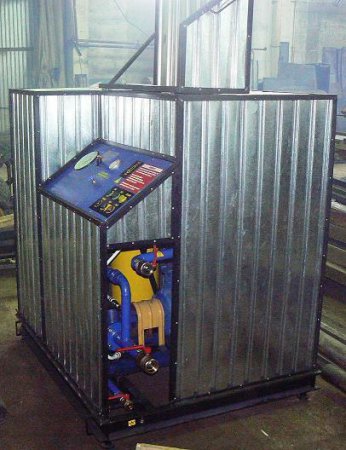

The cavitation hydrodynamic unit UKG-14 is a single unit that includes a pump, a filter (as needed), an RAF-14 apparatus, pipe interchanges, a control and automation unit, and a metal case that protects the installation from external influences.

Purpose of the installation UKG-14

- Obtaining water-fuel oil emulsions resistant to delamination (for burning in boilers of any type);

- Utilization of liquid sludge fuels and lubricants together with contaminated water;

- Getting winter diesel from summer ;

- Obtaining suspensions.

Variant of work UKG-14 for fuel-water emulsion

Under the action of the vacuum created by the switched-on pump (s) in the supply pipe, fuel and water enter the pump inlet. The pump is pre-mixed. The water-fuel mixture is supplied under pressure to the RAF -14 apparatus . The mixture is forced through the rotating holes of the rotor and the fixed holes of the stator. The geometry and kinematics of the rotor and stator are selected in such a way that conditions are created for intensive cavitation. Under the influence of cavitation, water is emulsified in the fuel. The result is a water-fuel emulsion.

Performance variations

Equipment may include additional lines for the accurate and uniform dosing of additives and chemicals to modify the feedstock. It can be delivered in various variations:

- Semi-automatic performance. In which, for the operation of the equipment, our specialists learn the operator who maintains the installation and regulates the processes.

- Full automatic execution. In which all processes are controlled by a computer designed exclusively for the needs of the customer, the presence of the operator in this configuration is minimized.

To purchase the UKG-14 cavitation installation, contact the sales department at the numbers indicated on our website or leave a request in the feedback form.

Technical characteristics of the cavitation unit UKG-14

| Supply voltage,V | 380 |

| Installed power, kW | 13 |

| Throughput, m3/h | up to 18 |

| Diameter of inlet pipe, mm | 50 |

| Diameter of outlet pipe, mm | 40 |

| Diameter of a branch pipe for water supply, mm | 15 |

| Temperature of working fluid (medium), °C | 50-90 |

| Weight no more than, kg | 550 |

| Ambient temperature °C | 5-40 |